Streamlining Optical Fibre Production with the Advanced Optical Fibre Diameter Analyser

Streamlining Optical Fibre Production with the Advanced Optical Fibre Diameter Analyser

Blog Article

Just How an Optical Fibre Diameter Analyser Enhances Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser into Fibre manufacturing processes represents a substantial advancement in top quality control techniques. By using real-time, precise measurements of Fibre diameters, this technology resolves the critical requirement for uniformity in manufacturing standards.

Relevance of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is important in the field of optical Fibre technology, as it directly affects the efficiency and reliability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying capacity, depletion, and overall transmission performance. Precision in measuring Fibre Diameter guarantees that the optical buildings are preserved within specified tolerances, which is important for optimum signal stability.

Variations in Fibre Diameter can bring about boosted losses as a result of spreading and modal diffusion, affecting the top quality of information transmission. In high-speed communication systems, such inconsistencies can result in substantial destruction of signal quality, leading to data errors and decreased efficiency. Consistent Fibre Diameter is necessary for compatibility with connectors and splicing technologies, which are indispensable components of Fibre optic networks.

Quality control procedures in Fibre manufacturing greatly count on accurate Diameter dimensions to make certain conformity with sector standards. By executing durable dimension methods, makers can enhance product integrity, reduce waste, and boost overall system performance. Thus, the significance of Fibre Diameter dimension can not be overstated, as it functions as a keystone in the advancement of optical Fibre innovation and its applications in contemporary interaction networks.

Exactly How the Analyser Functions

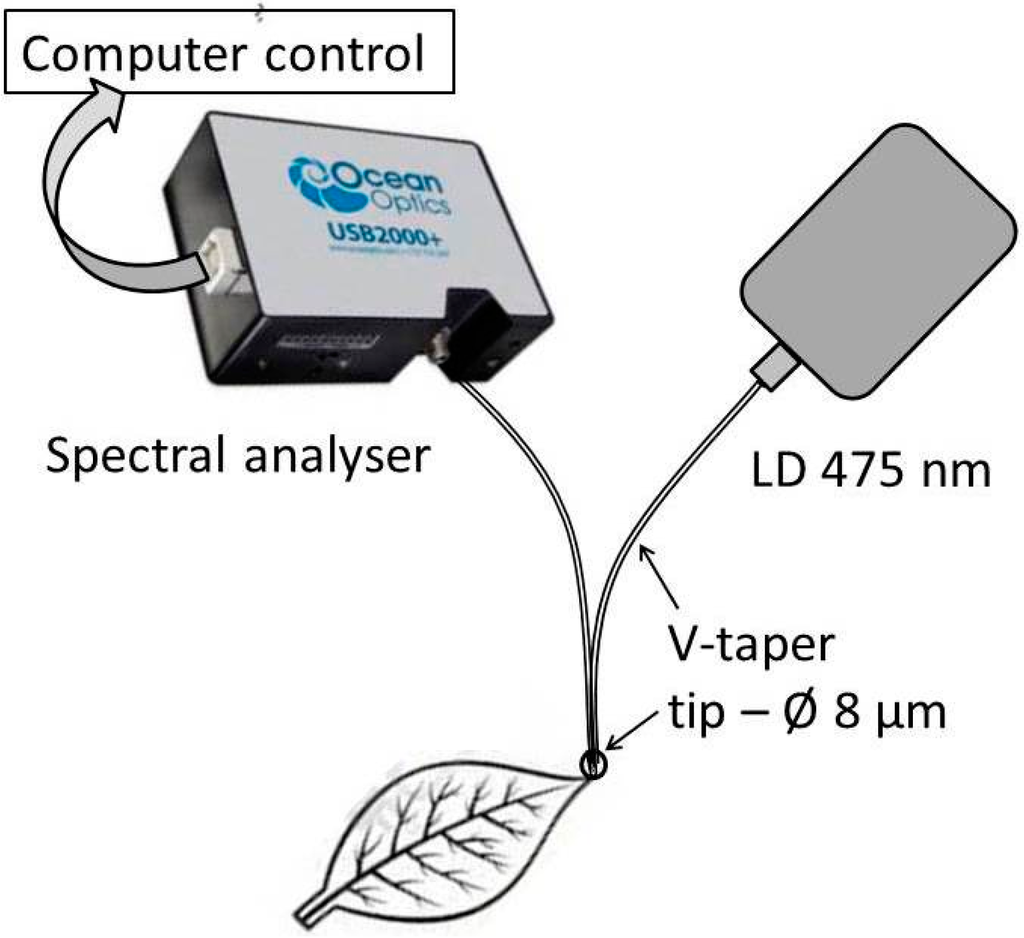

The effective measurement of Fibre Diameter counts on advanced analytical techniques that guarantee precision and integrity in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser modern technology and progressed photo processing algorithms to accurately evaluate the Diameter of fibres as they are produced

Initially, a laser beam of light is directed at the moving Fibre, producing a cross-sectional shadow. The analyser captures this shadow utilizing high-resolution video cameras positioned purposefully along the manufacturing line. The captured images are after that processed in real-time to figure out the Fibre's Diameter with phenomenal precision.

The system makes use of sophisticated formulas that make up various factors, including variations in light intensity and environmental conditions, to boost measurement integrity. It can spot minute modifications in Diameter, such as fluctuations that could happen during the manufacturing process.

In addition, the analyser is capable of taking care of several fibers all at once, increasing throughput without compromising precision. By offering rapid responses on the Diameter, the Optical Fibre Diameter Analyser plays an essential function in preserving rigid quality assurance standards, making sure that the end product meets sector requirements and client requirements.

Benefits of Real-Time Tracking

While standard techniques of checking Fibre Diameter usually entail lengthy post-production checks, real-time tracking considerably improves the efficiency and quality of optical Fibre manufacturing. optical fibre diameter analyser. This proactive method enables producers to identify inconsistencies in Fibre Diameter as they occur, instead of waiting up until production is full to analyze top quality

By constantly measuring the Diameter during production, suppliers can make sure that the fibres meet rigid specs, leading to decreased variability and boosted consistency. Real-time tracking likewise makes it possible for prompt corrective actions to be taken, reducing waste and stopping malfunctioning fibers from going into the supply chain.

Furthermore, this modern technology promotes enhanced data collection and analysis, offering insights right into production patterns and potential areas for enhancement. Such data-driven decision-making empowers manufacturers to click maximize processes and preserve high criteria of quality control.

Additionally, real-time tracking promotes a society of constant renovation within the manufacturing setting. Workers are more engaged when they can see the impact of their operate in real-time, resulting in increased accountability and a commitment to quality. In general, the application of real-time monitoring systems in optical Fibre manufacturing equates to premium item quality and raised consumer contentment.

Effect On Manufacturing Efficiency

Implementing optical Fibre Diameter analysers significantly improves production performance by simplifying the manufacturing process. These devices facilitate continual monitoring of Fibre Diameter, enabling manufacturers to discover discrepancies in real-time. By identifying variances without delay, assembly line can be adjusted rapidly, minimizing downtime and decreasing the probability of producing defective items.

Additionally, the assimilation of these analysers into the manufacturing workflow allows much better source appropriation. With precise Diameter measurements, drivers can enhance product use, ensuring that sources are not thrown away on problematic fibres. This accuracy likewise adds to less revamp and ditch, eventually decreasing production prices.

The automation given by optical Fibre Diameter analysers lowers reliance on hand-operated examinations, which are commonly taxing and prone to human mistake. Therefore, workers can concentrate on more critical tasks, optical fibre diameter analyser enhancing overall productivity.

In addition, the information created from these analysers can inform process improvements and promote far better decision-making. By analyzing trends in Fibre Diameter variations, producers can view it execute proactive measures to enhance manufacturing strategies and maintain regular high quality. In summary, optical Fibre Diameter analysers play an important duty in increasing production performance, causing better outcome and enhanced success.

Instance Researches and Success Stories

Throughout various markets, instance research studies highlight the transformative effect of optical Fibre Diameter analysers on manufacturing procedures. One prominent example is a leading telecoms firm that faced challenges with irregular Fibre diameters, resulting in raised being rejected rates. By incorporating an optical Fibre Diameter analyser, the business achieved real-time tracking of Fibre dimensions, leading to a 30% decrease in flaws and considerable price savings.

Additionally, a research study establishment focusing on sophisticated materials utilized optical Fibre Diameter analysers to refine their experimental processes. The analyser's ability to provide comprehensive insights right into Fibre uniformity enabled the growth of ingenious products with enhanced efficiency features.

These success tales underscore the important duty of optical Fibre Diameter analysers in boosting quality assurance, enhancing manufacturing performance, and driving technology throughout varied industries.

Final Thought

To conclude, the Optical Fibre Diameter Analyser plays a pivotal role in enhancing high quality control within Fibre production. By supplying exact, real-time measurements and helping with instant rehabilitative activities, this innovation considerably decreases irregularity and lessens waste. The execution of such innovative tools promotes a culture of continuous renovation and operational efficiency, ultimately guaranteeing compliance with sector standards and keeping competition. As shown via numerous study, the analyser proves vital for attaining premium product quality in Fibre manufacturing.

The execution of optical Fibre Diameter analysers permitted for rigorous top quality control, making certain that the produced fibers met exacting industry criteria.In final thought, the Optical Fibre Diameter Analyser plays an essential function in improving high quality control within Fibre manufacturing.

Report this page